Policy and demand are the five major development trends of semi-trailers.

Release time:

2018-06-16 01:14

Source:

As the main force of domestic cargo transportation, semi-trailer is one of the most familiar models for card friends. The future development trend of semi-trailer directly affects the efficiency of road transportation. In the future, semi-trailer development will have what development trend?

● Trend 1: Lightweight, more cargo loading

With the development of national activities to control vehicles, the current long-distance semi-trailer basically belongs to the standard load transport. Under the premise of the total limit unchanged, how to reduce the weight of the vehicle has become the most concerned problem. Semi-trailer lightweight once again by everyone's attention.

To reduce the weight of semi-trailers, car factories have also tried various methods. For example, many trailer factories use lighter aluminum alloy materials to make semi-trailers. The traditional steel semi-trailer will use steel with better strength, and further reduce the weight of the vehicle by punching special-shaped holes in the beam.

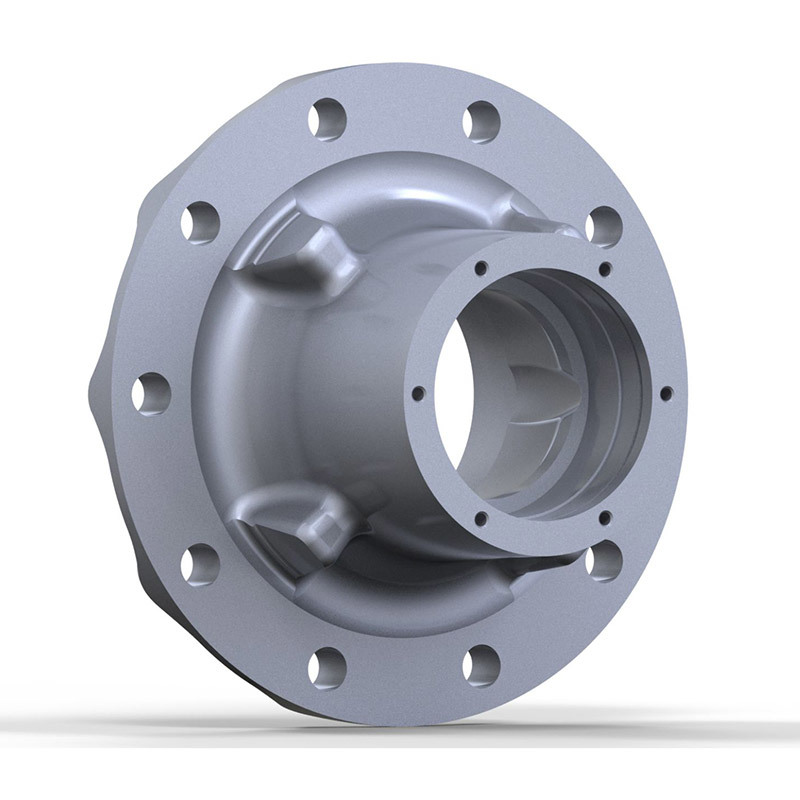

In order to reduce the weight, the use of large single tire with Juncheng forged aluminum alloy wheels is also a big development trend. Compared with the traditional twin tires, it can reduce a certain weight, load more goods, and improve the operating income of the whole vehicle. At the same time, compared with twin tires, large single tires have smaller contact area with the ground, lower resistance, and better fuel economy.

● Trend two: intelligent, semi-trailer will be more and more intelligent

Intelligence is now mentioned more words, before the tractor on the high-tech is now also applied to semi-trailer. For example, the tire pressure monitoring technology realizes the automatic monitoring of the tire pressure of the semi-trailer. If the tire pressure is abnormal, the system can notify the vehicle driver in time to repair the semi-trailer tires to ensure transportation safety and improve transportation efficiency.

In addition, domestic semi-trailers are now equipped with automatic inflation and deflation systems to inflate and deflate the tires that have lost pressure in time, so that the tire pressure is always at the normal pressure value, reducing the probability of tire blowouts and increasing the service life of the tires.

It is understood that in terms of semi-trailer disc brakes, some German companies have designed brakes with brake disc wear warning sensors. When the brake disc is worn to the warning position, the sensors can feed back the information to the driver in time, thereby improving driving safety.

● Trend 3: Compliance, disc brake airbags will be popular

With the rectification of car carriers and the strict implementation of over-limit transportation management regulations, the future semi-trailer transportation will be more standardized. Those ultra-long and ultra-wide semi-trailers will become history in the near future, and the future semi-trailers will be more compliant.

In addition to the outer dimensions of the semi-trailer, the load capacity is more compliant and the chassis configuration is more standardized. According to the new regulation GB7258, starting from January 1, 2020, three-axle fence type and warehouse fence type semi-trailers must be equipped with disc brakes, and dangerous goods transport vehicles must use disc brakes one year in advance. The new regulations give car companies and truck drivers two years as a buffer. It can be seen that the trailer chassis accessories will be more standardized in the future.

In addition, GB7258 also stipulates that in the future, airbag suspension will be used for models such as three-axle fence type and warehouse fence type semi-trailer. The use of airbag suspension on semi-trailers can make the vehicle's shock absorption effect better. In addition, the trailer axle can be raised when the vehicle is unloaded, reducing the friction between the tires and the ground, reducing vehicle fuel consumption, and improving fuel economy.

● Trend four: high efficiency, semi-trailer maintenance mileage longer

Nowadays, China's logistics has developed rapidly. Whether it is a logistics company or an individual retail customer, the annual mileage of trucks is constantly increasing. It is normal to run 150000 kilometers a year. For the vehicles of some trunk logistics companies, the mileage is often longer than 300000 kilometers.

At present, most ordinary axles are maintained once every 100000 kilometers. For example, special line logistics runs 300000 kilometers every year, and the axle head needs to be maintained three times a year. This not only delays the operation efficiency of the vehicle, but also distracts the user's energy. The use of long maintenance axles can put more energy on the operation of the vehicle. For example, BPW 400K axle can realize 400000km long maintenance of axle head. Long maintenance axle like this can better improve the operation efficiency of semi-trailer. In the future, semi-trailers will become more efficient, and axle maintenance mileage will be focused.

It is worth mentioning that the future of semi-trailer efficiency, not limited to the long maintenance of the axle. For example, the wheel hub power generation axle developed by BPW. After the axle is equipped with a wheel hub power generation system, it can output electric energy during driving and braking, and its electric power can be supplied to the refrigerated semi-trailer. For example, semi-trailer mounted solar panels, power generation, the use of these technologies will also make semi-trailer become more efficient and energy-saving.

● Trend five: specialization, semi-trailer special car will be inevitable

For a long period of time before, many semi-trailers pulled goods that did not match their own operating conditions for transportation on the road, which not only disrupted the market order, but also had greater safety risks. For example, ordinary fence trailers pull some liquid goods transported by tankers, and some fence semi-trailers buy quilts to pull frozen goods. This mode of transportation is likely to cause thawing of goods and affect the quality of goods.

With the increasingly stringent national laws and regulations, people's awareness of production safety has improved, and more and more attention has been paid to semi-trailer special vehicles. For example, box-type semi-trailers pull light throwing goods and express delivery, while refrigerated trucks transport frozen goods and vegetables. Special car is more conducive to the healthy development of the logistics industry, so the future development of semi-trailer will be specialized.

The restrictions of laws and regulations and the needs of the market determine the future development direction of semi-trailers. In the future, semi-trailers will develop in the direction of lightweight, intelligent, compliant, efficient and professional. This is related to reducing the user's use cost and the vital interests of users. Semi-trailer factories are also doing their best to develop and improve in these directions to produce better products to meet the needs of users and promote the efficient development of domestic materials.

Other dynamics

According to the "Notice of Shandong Provincial Department of Ecology and Environment on Issuing the List of Enterprises Implementing Compulsory Cleaner Production Audit in Shandong Province in 2023" (Lu Huan Zi [2023] No. 36) and "On Issuing the List of Enterprises Implementing Compulsory Cleaner Production Audit in Liaocheng City in 2023", Shandong Juncheng Metal Technology Co., Ltd. is included in it and should carry out cleaner production audit in a timely manner. Our company has fully started the cleaner production audit from April 2023 to December 2023, and passed the cleaner production audit acceptance on January 23, 2024.

Shandong Juncheng Metal Technology Co., Ltd. Cleaner Production Audit Information Publicity

In order to consciously fulfill the obligation of protecting the environment, actively accept social supervision, implement the relevant provisions and requirements of the "the People's Republic of China Cleaner Production Promotion Law", "Cleaner Production Audit Measures", "Cleaner Production Audit Evaluation and Acceptance Guidelines" and other documents, combined with the actual production of our company, formulate the content of cleaner production audit publicity.

Qilu Network Lightning News, September 13-from September 13 to 17, the main media of the central government stationed in Shandong and provinces and cities carried out a progressive theme interview activity of "the Yellow River into the Sea", showing the brilliant achievements made by Shandong in keeping in mind the entrustment, strengthening ecological environmental protection, and taking the road of green, sustainable and high-quality development. On September 13, the interview team entered Liaocheng Shandong Juncheng Metal Technology Co., Ltd.

As we all know, wheels have many different diameters, ranging from 14 inches to more than 24 inches, but at the same time, the wheels also have different widths. The width of the wheels not only affects the installation of the wheels on the car, but also affects the tires on the wheels. The installation on the top, I will introduce it in detail for you below. The size of the hub is defined as "diameter x width", so a 17-inch hub may be 17x 7.0,17x 7.5 or 17x8.0. The width of the hub usually increases in proportion to its diameter, so you can hardly see a 17x 5.0 or 17x 10 hub, the standard size is 14x

At present, there are three different types of wheel hub polishing: traditional polishing, fine turning and wire drawing, all of which are based on the technology of polishing the wheel hub to produce bright metal primary colors, but their methods, effects, necessary protection methods and maintenance methods are very different. In a series of exquisite, durable or easy to maintain made, polishing breaks the inherent barrier of coating and electroplating, and combines the two, especially after the appearance of transparent paint, polishing makes the wheel more exquisite. Traditional polishing Traditional polishing, also known as ball throwing, usually uses a series of soft materials to polish the hub until the surface shows a deep metallic luster. Old-fashioned polishing wheels generally do not apply transparent paint, which

Wheel hub made: electroplating

Many car manufacturers offer electroplated wheels as an alternative, and most aftermarket wheels of 20 inches or larger are also electroplated. Electroplating is a kind of beautiful, but it is also fragile and expensive to repair. Electroplated wheels are usually polished and acid etched first, and then plated with a layer of nickel, copper, and chromium in turn. The coatings are bonded to each other to increase strength, so that the electroplating is completed. Because there is no need to apply clear paint, it usually needs to be carefully cleaned with soap and water, and then touched up with cotton wool impregnated with metal polish. The electroplating process seems to give the aluminum wheel some kind of brittleness, making most of the plating wheel easy to break in the collision, this kind